Share This Page

Share This Page| Home | | Sailing | | Alaska 2009 | |  |  |  Share This Page Share This Page |

Copyright © 2009, P. Lutus. All rights reserved. Message Page

(double-click any word to see its definition)

Breakdowns and Repairs

This is a recitation of particular breakdowns I experienced this year, selected from a long list for their possible educational value to other boaters.The Everything Box

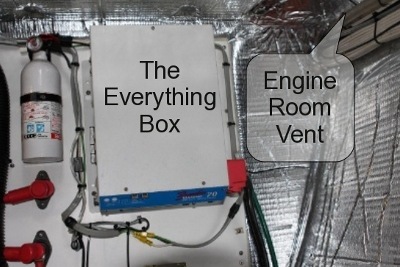

Impeller Pumps Figure 1: engine room view

Figure 1: engine room view

(before salt water bath)Many modern yachts have a rather large, specialized electronic box below decks that combines two important functions — it generates house wall-socket power (an "inverter") and it charges the boat's batteries. There are a number of advantages to combining these functions — one is that you only have to buy and install one box, also it's economical to join separate functions in a single enclosure. Another advantage is that one needs just one set of large battery cables, needed for carrying the large currents to the batteries when they are being charged, and from them when they are being discharged.

All this reasoning depends on the idea that nothing will go wrong, because if the Everything Box should fail, you lose both the inverter and the charger, and you need them both. As it turns out, the Everything Box couldn't have been a worse choice for my boat and my activities.

This season I made my way to Gore Point, southwest of Seward and a logical starting point for a long passage across the entrance to Cook Inlet, a famously rough patch of water that leads to Kodiak Island. The following day, the weather report called for 25 knot winds and seven-foot seas. Those who regularly make this passage understand that the sea conditions can be dramatically worse when wind and tide are in opposition, and because of the time required for the passage and the nature of the landscape, opposing wind and current must be true at least some of the time.

Toward the end of my passage to Kodiak Island, the tide turned and began to oppose the 25-knot wind. The seas rose to about the forecast height of seven feet, but very short and steep, with some waves breaking. The sea began to pound my boat from the side, a particularly vulnerable direction. I emphasize this was not a particularly serious or abnormal situation for Alaska in the summertime. But nature had a surprise for me — one wave broke against the side of my boat with perfect timing — at the precise moment the wave broke, it collided with the starboard engine room vent, an open path from the outside to the inside of my boat. I later discovered this caused a fountain of salt water in the engine room, which drenched the Everything Box. Within a second or two, the Everything Box became a Nothing Box — all my equipment that relied on house power abruptly ceased to function, and the distinctive smell of an electrical fire wafted from the engine room.

During a later inspection I discovered that the Everything Box, touted as suitable for the marine environment and priced accordingly, had ordinary, bare circuit boards inside, and because the solid-state inverter must handle rather high voltages, even a small amount of salt water can and will produce a spectacular failure. In this case, the unit self-destructed in a dramatic way, burning and melting its insides beyond repair (the Everything Box manufacturer claims they now coat their circuit boards to try to avoid this problem).

When I got to Kodiak and after some thought, I decided to replace the Everything Box with individual components, each of which would be much easier to repair or replace:

- A battery charger.

- A house power inverter.

- A way to automatically switch from shore power to the inverter's output when the inverter is activated.

Basically, the above list summarizes what the Everything Box does, but broken down into separate elements that are more easily repaired or replaced in the field. Two of the items in the list can be gotten virtually anywhere, but the third cannot be gotten at all — it must be built from scratch, by someone who understands electronics and who has practical skills. Since I designed electronics for the NASA Space Shuttle many years ago, I decided I was up to the task.

A little digression — young people may not realize Americans didn't always buy everything ready-made. It wasn't so long ago that, when confronting a technical problem, people would consider the option of building something from scratch. For example, when I was a teenager I would wait eagerly for my neighbor's TV sets to break down, then I would acquire them and turn them into Ham Radio transmitters and receivers. This was in an era before computers, even before transistors, if my readers can imagine such a thing.

And guess what? Radio Shack stores were once — how shall I put this? — radio shacks. In modern times one is tempted to assume the "Radio Shack" name is just a clever marketing ploy, meant to inspire visions of a small storefront filled with racks of electronic parts, overseen by an avuncular pipe-smoking electronics prodigy. But Radio Shack stores once really were radio shacks, places where you would buy parts for your next project, and they carried almost no finished goods at all.

With rare exception Americans don't design and build stuff any more. We've become consumers — we consume electronic gadgets the same way we consume ideas, without giving much thought to creating any of our own.

Anyway. I bought some parts in Kodiak and put together a replacement for the Everything Box. The total bill for the parts was substantially less than the cost of a replacement Everything Box, and I knew if anything went wrong, I could easily get replacement parts even in a small Alaska fishing village.

A digression. For a boat owner who primarily travels between marinas, who rarely or never drops his anchor or experiences rough conditions, the Everything Box is a perfectly reasonable technical solution — it does a lot of things well, and it delivers much more power as an inverter, and much more current as a battery charger, than my replacement does.

My solution is robust and resilient, but it requires the boat owner to know more than most people do. The problem with the Everything Box is that it risks what is called a "single-point failure" of massive proportions — a single breakdown caused by a tiny bit of salt water can take out the inverter, the battery charger, and the ability to connect to shore power. Such a single-point failure scenario may sound overly pessimistic, but don't forget, dear reader ... it happened to me.

Readers who want more technical depth about this project should click here.

Anchor Winch Figure 2: Aground in Icy Bay

Figure 2: Aground in Icy Bay

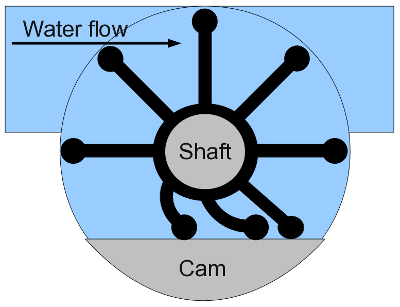

Figure 3: Impeller Pump

Figure 3: Impeller PumpMy boat has two impeller pumps — one on the generator, one on the engine. I will say frankly that impeller pumps are about the worst invention ever conceived by man, on a par with the leaf blower (instead of dealing with your own leaves, you blow them into your neighbor's yard) and the consent decree ("I didn't do anything wrong, and I promise not to do it again").

Impeller pumps are to boats what Microsoft Windows is to computers — the worst imaginable solution, but one that has become universal through persistence and lack of imagination. The reason is that, if allowed to go dry, the impeller begins to self-destruct through friction against its housing. And even if operated correctly, these pumps have very short lives because of a cam that applies constant pressure against the impeller from one side, which stresses and wears out the pump's bearings.The impeller pumps each draw salt water into the boat to cool a diesel engine, of which I have two — the boat's engine and a 5 kilowatt generator. But if anything should interfere with the free flow of water, the impeller inside the pump (the black rubber cylinder with the vanes sticking out in Figure 3) continues to spin against a dry metal cylinder — and the offset cam — until the impeller catches fire and disintegrates. Because this can happen in a matter of minutes, impeller pumps must never be allowed to run dry.

I can't tell you how many times I've repaired the impeller pump on my diesel generator after the raw water intake sucked up a piece of seaweed, which interrupted the flow of water to the pump and destroyed the impeller. This is such a frequent task that I've rearranged the engine room to allow easy access to the impeller pump, and I have a large stock of spare impellers on hand.

But until this season, the much larger impeller pump on the main engine has been spinning along quietly, revealing no hint about how unhappy it was, and how close to failure. As to consequences, the two pumps aren't equal — if the generator's impeller pump quits, I can't charge my batteries while at anchor or make dinner with my microwave oven. Not very serious. But if the engine's impeller pump dies, I can't run the boat. Very serious.

As explained elsewhere, as I slept soundly my boat beached itself during a high wind in Icy Bay, a wild, remote place in central Alaska with no rescue options (except self-rescue). The next morning as the tide fell, fully aware of the seriousness of my plight and a bit anxious to get off the beach, I briefly started the engine to see if I could move the boat before the tide descended further and left my boat high and dry. In a matter of minutes I determined that the boat was firmly planted and I would have to wait for the tide to fall and rise again before refloating my boat.

But by starting the engine under those circumstances, I had sealed the fate of the pump's impeller. What I didn't realize was the pump's water inlet was already sitting on the sand, unable to draw water, and it only took a few minutes to destroy the impeller.

Later that morning, after I refloated the boat, I started the engine and moved to the middle of Icy Bay. Then, oblivious to the drama about to unfold, I let the boat drift with engine idling as I made departure preparations. Just as I was ready to leave, the engine's high-temperature alarm went off and I realized I had a serious problem. I dropped my anchor and shut down the engine.

Fortunately I carry a spare impeller for this pump also, but it is much larger, not easy to swap in the field. In an epic struggle I managed to swap impellers with ordinary hand tools, but it became clear that the engine pump was rather completely worn out and would have failed even if I hadn't abused it on a sandy beach. I eventually nursed my boat home and replaced the entire pump.

Isn't it ironic that impeller pumps tend to be used in circumstances where their source of water seems almost certain to be blocked?

AutopilotDuring my around-the-world sail, I had a manual anchor winch. It was safe and reliable but required a lot of energy to operate. Now that I have a power boat (now that I am no longer pure) and my anchor and rode are much heavier, I have an electrically operated power winch. There are horror stories about these winches — stories where people lose limbs when the winch goes out of control and the operator gets tangled up.

But how could the winch go out of control? There are two pushbuttons next to the winch — one raises the anchor, one lowers it. What could be simpler? Well, as with most things in life, a close look reveals some ingenious failure modes. To make the winch motor turn, the operator pushes a button, but the button only activates a big relay meant to handle the high currents required by the six horsepower electric motor. At 746 watts per horsepower, six horsepower is 4476 watts, which at 12 volts requires a current of 373 amperes. That's a lot of current. Below decks a special motor controller handles these currents, under control of the pushbuttons.

The winch's controller is a low-tech, not to say primitive, device that switches the motor on and off by making and breaking the electrical path between the batteries and motor. To handle the required current, the controller has big contact surfaces. So what could go wrong? Well, each time the controller operates, the big contacts smash together quickly, but there's always a spark just as contact is made or broken (imagine a Frankenstein movie with sparks flying around). Each spark vaporizes some of the contact surface, until the surface is pitted and rough. Over a period of years this contact surface ends up looking like the surface of the moon — and because the same current is now flowing across a rough surface, the possibility exists that the contacts will permanently weld to one another and refuse to react to the pushbuttons. Very, very bad.

Okay, back to reality. I've always wanted to visit a group of islands located off the entrance to Cook Inlet — the Naked Island group. This season I decided to visit and chose a suitable place to anchor. But as with all such expeditions where I might leave the boat unattended for hours, I have to be particularly careful about anchoring. On my first try the wind was brisk, the anchor didn't set properly, so I decided to raise the anchor and try again. I pressed the winch's "up" pushbutton, and the winch began to raise the anchor. But I discovered the pushbutton was no longer controlling the winch — the contacts had fused together as described above, and the winch was permanently connected to the batteries. I stood in shock as the winch began to raise the anchor rode and anchor, brooking no interference from a human frantically pushing an unresponsive button.

Now out of control, the winch dragged the boat forward through the water, and I thought about what might have happened if I had become tangled in the anchor rode. I was far from civilization and almost as far from the circuit breaker that could have stopped the winch. I quickly figured out what had happened, and realized I had never considered this particular failure mode. But later on, while examining the controller's low-tech interior, I saw that this failure was inevitable — as explained above, each operation of the controller produces a little electrical arc (imagine tiny flashes of lightning). The arcs dig little pits in the contact surface. Little pits become big ones, over time the arcs become bigger and more energetic, until finally the contact surfaces melt together and the controller fails.

Figure 4: Plane crash near Homer, Alaska.

Figure 4: Plane crash near Homer, Alaska.

Reason: ran out of gas.Dear reader, thanks for reading all that technical stuff, but this leads to an important philosophical question — do boat owners really need to know all this stuff? Well, yes, to be relatively safe, they do. In the final analysis, boat operators have these choices:

- Other-reliant: Stay close to marinas, keep the radio turned on, be ready to call Vessel Assist at a moment's notice.

- Self-reliant: Learn how boats operate, carry an absurd number of tools and spare parts, become skilled at performing repairs in the field.

- Unreliant: Take huge risks in wild places while operating a vessel whose internal workings are a mystery.

I've rescued a lot of boats over the years and based on that, I know most people take option (3), but without reflection or analysis. Most boat failures arise from silly causes — ran out of fuel, battery too old and marginal to start the motor, badly maintained engine seized up. It's the same with airplanes and cars — in modern times, people are less able or willing to accept personal responsibility.

LED LightsThe autopilot reads an electronic compass and automatically steers the boat. Now to a car owner that may seem like a luxury item, but when you travel over 5,000 nautical miles in a season as I do (a distance that requires about 600 hours of travel time), it isn't realistic to consider hand-steering the boat.

A digression — During my around-the-world solo sail, an autopilot was even more critical — that journey covered 30,000 miles at an average speed of four knots, for a total of 7500 underway hours — that's almost a year of total boat steering time, distributed across the four years that journey required. I learned how to keep the autopilot running at all costs.

Anyway. I was visiting Larsen Bay on the west side of Kodiak Island, preparing to cross Shelikof Strait and take more bear pictures during an upcoming low tide. The idea is that during low tide, the bears walk around in the open hunting for clams.

But the morning I planned to depart, I discovered I couldn't activate the autopilot, which gave an error message that it couldn't read the electronic compass. I had to figure out whether the problem was the electronic compass or the autopilot itself. The electronic compass is a comparatively inexpensive part, but it is also very simple and unlikely to fail. The autopilot is much more expensive (about $1,600 in 2009) and much more complex.As I hand-steered my way back to Kodiak City to order parts, I considered my options — it would require a week to place an order and get delivery, so any decision I made should be carefully thought out. I decided the problem was the autopilot itself, the "brain" that collects various bits of information and steers the boat by way of a hydraulic rudder actuator.

I ordered a new autopilot and waited for delivery, thus missing a very low tide and a chance to photograph bears on the wild Alaska Peninsula. And it turned out I had guessed right — the problem really was the autopilot, I had ordered the right thing, and the new autopilot is better than the old in a number of ways.

This season is my eighth year operating this boat, and during that time I've replaced virtually all the original electronics — the radar, the satellite dish, the autopilot, most of the cockpit displays, the inverter/charger described above, and several computer displays meant to show a nautical chart with my course superimposed. Essentially everything.

When you read an advertisement claiming that a particular piece of gear is priced higher than normal because it's specially designed for the nautical environment, you should listen to the voice of experience — it's bunk.

Figure 5: Aircraft-style

Figure 5: Aircraft-style

low-voltage light fixtureI end this page on a positive note. During the winter layover I considered the idea of replacing all my boat's incandescent lights with the new LED lights — very efficient, solid-state light sources that are much more durable and reliable.

An incandescent light is a technological throwback. Most of its power is wasted generating heat instead of light (hey — it sounds like I'm describing a politician), it has a very short life, its only advantage is that it's cheap. A well-chosen LED light produces the same amount of light with only a tiny fraction of the power, generates much less heat, and lasts much longer.

LED lights are sufficiently mature that they're nearly ready for mass adoption in people's houses (as compact fluorescent lights (CFLs) already are), but in the case of a vessel that must generate its own power at higher cost, the economy calculation already favors LED lights over incandescents.

During my research, I realized something. First, my boat has a lot of aircraft-style light fixtures, little circular fixtures with a small incandescent bulb such as one might see on a commercial airliner (see Figure 5). Second, because commercial airliners must generate their own power and therefore have the same priorities a boater does, I thought I might find a plug-in LED replacement for the original incandescent lights. And that turned out to be correct — there is such an LED light in mass production. It fits into my fixtures, it's very efficient, and it isn't terribly expensive given that it represents cutting-edge technology. Here's a chart that compares the old and new lights:

Incandescent LED Picture

Description Ancor 529371 incandescent light LEDLight.com 85529 LED light Current, amperes 1.67 0.175 Power, watts 21.0 2.2 Lifetime, hours 2,000 10,000 Unit Cost, $US $6.23 $17.00 Notice that the incandescent light requires almost ten times the power of the LED light. I had hoped to compare brightnesses using technical descriptions, unfortunately the Ancor light advertising doesn't reveal this kind of information. All I can say is the warm-white version of the 85529 LED light looks very much like the Ancor light in side-by-side comparisons — in both color and brightness.

I caution my readers that the LED light business is just getting started and there is a lot of junk out there. I have bought a number of LED lights for other roles on my boat that turned out to be very poor, erratic in operation, unreliable or not nearly as bright as advertised. The main reason I used the 85529 light for my example is because it has been the most reliable of all the LED lights I bought, such that I pressed it into service in fixtures where it didn't actually fit very well.

I got the idea for this project one day in Alaska when I realized how much power the lights required. I listed my boat's power requirements while at anchor. I have a refrigerator that requires 6 amps but only runs about 20% of the time, and I run the house-current inverter in the evening, but a modern inverter is very efficient, only requiring a little more power than the appliances that are connected to it. After some number crunching I realized the single biggest power drain was the incandescent lights — I counted 15 and each required 21 watts, a total of 315 watts or 25 amps. Obviously I didn't run all these lights continuously, but even a small fraction of this load would overwhelm any other power use.

The new LED lights are much more efficient, requiring only 33 watts altogether, and they last five times longer than the incandescents. The effect of this change is noticeable when I am at anchor in Alaska (which is most of the time) — I don't have to run the generator nearly as long to replenish the house battery bank.

This was a worthwhile project — not very expensive, and not very difficult either. And with a big long-term payoff.

| Home | | Sailing | | Alaska 2009 | |  |  |  Share This Page Share This Page |